What is a desiccator?

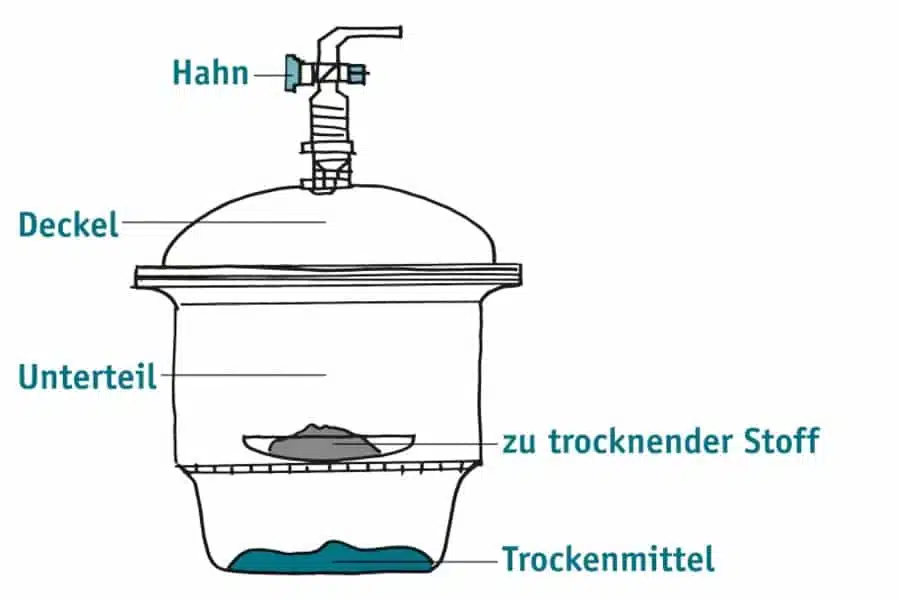

A desiccator is a device for controlling humidity. It consists of a container and an absorbent layer known as a sorbent. The container is vacuum-sealed and usually contains silica gel or calcium chloride as the absorbent.

Storing solids under vacuum and above a desiccant such as calcium chloride stored in the base removes water or volatile solvents in order to subsequently determine the yield correctly or to avoid contamination in subsequent analytical tests.

Areas of application for desiccators

Desiccators are often used as part of a process engineering concept to remove liquids from gas streams. However, they can also be used to remove water from organic solvents or to remove water vapor from air or other gases. They can also be used to remove moisture from various substances – for example in the pharmaceutical and food industries – and to ensure the purity and integrity of reagents.

Desiccators are particularly useful when it comes to improving the quality of a product and reducing process costs. For example, using a desiccator can help a product to dry faster, which can simplify the cleaning process and ultimately save costs.

The use of a desiccator is also advantageous in food processing. By using the appliance, the drying result can be improved and the time required for the drying process can be reduced at the same time.

How does a desiccator work?

The primary purpose of a desiccator is to maintain the relative humidity inside it at a certain level – usually below 10-15% relative humidity – by absorbing and binding the air. Most desiccators achieve this by using adsorbents such as silica gel or calcium chloride, which help to absorb excess moisture and hold it on the surface of the sorbent. In this way, a stable relative humidity can be maintained inside the appliance so that sensitive products or materials can remain protected.

What types of desiccators are there?

Desiccators are available in different sizes – from handy models for the workbench to large-format station models with capacities of several liters – but all models differ fundamentally in their design and the adsorbent used (silica gel or calcium chloride).

When working with a desiccator, various points must always be observed:

- Always check that there is still a vacuum before opening.

- The grindings must be well greased so that the vacuum is permanently maintained.

- Open the desiccator lid: Although opening is sometimes difficult, force should only be applied in moderation to avoid damage. A special desiccator opener can be used to help.

- Fabrics to be dried should be protected from turbulence during ventilation by aluminum foil or similar.

Application of desiccators at Ebbecke Verfahrenstechnik

A desiccator is a chemical laboratory device that we at Ebbecke in Bruchköbel mainly use to dry solid chemical substances. We would be happy to provide you with further details, advantages and possible applications.

Literature source:

The glass in the chemical laboratory / J. Friedrichs, F. Friedrichs / 2013