What is Centrifugal Screening?

Centrifugal screening refers to the process of screening through the targeted use of centrifugal force. It is primarily used for products that are difficult to screen and would clog up the screen feeders in conventional screening systems. This applies in particular to fatty and oily products and products with very light bulk densities.

Definition of centrifugal force

The term centrifugal force, also known as centrifugal force, is caused by the inertia of bodies and occurs in circular and rotary movements. According to the principle of inertia, centrifugal force refers to the inertial resistance that a body has to changing its direction of movement when following a curved path. On the other hand, there is the centripetal force, which is the cause of the change in the direction of movement. Both forces are in dynamic equilibrium with each other.

The carousel example:

If a child is riding a chain carousel and the father is watching, the two observers (child and father) feel different forces. The father only sees the centripetal force, which forces the carousel seat and therefore the child onto a certain circular path. The child, on the other hand, feels the centrifugal force created by the circular motion.

Areas of application of centrifugal screening at Ebbecke Verfahrenstechnik

Vibratory/rotary screening machines are used at Ebbecke Verfahrenstechnik for various tasks. The range of applications covers contract grinding, contract screening, protective screening and other processes for tasks and products with special requirements.

In detail, this includes

- Contract grinding of soft products without temperature increase

- Contract sieving of greasy products

- Contract sieving of oiled products

- Production of homogeneous grain structures

- Protective screening and dissolution of agglomerates

- Fractionation of energy-sensitive products

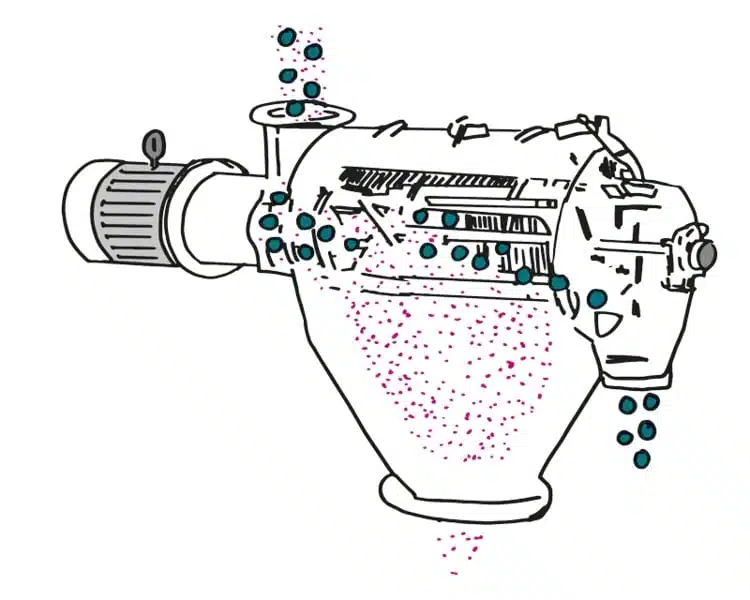

How the vibration/rotary screening machine works

The vibration/rotary screening machine at Ebbecke Verfahrenstechnik enables contract screening and subsequent contract filling of difficult-to-screen products. An eddy current bed is generated by means of a vane mechanism rotating in sieve half-shells, and the outer sieve mesh is kept free by vibration superimposition. The vibrating screening machine from Ebbecke Verfahrenstechnik works continuously, dust-free and quietly. The tensioning screen can be easily removed upwards after opening the holding device.

Advantages of vibration/rotary screening

Centrifugal screening, i.e. the vibration/rotary screening process, ensures that foreign bodies and impurities are reliably removed from powders and liquids. This is the basic prerequisite for the perfect quality of the end product. At the same time, the machines are designed to enable efficient production processes with low maintenance requirements.

Technical data:

Screen area: 0.5 or 0.9 m²

Mesh size: 75-10,000 μm

Parts in contact with the product: In stainless materials

Cleanability: Can be cleaned completely

Number of fractions: 2

Product feed: Via dosing screw, extendable

Throughput rate: Depending on mesh size and product

Would you like to find out more about Centrifugal Screening at Ebbecke Verfahrenstechnik? Contact us, we will be happy to help you!