What is suction pneumatics?

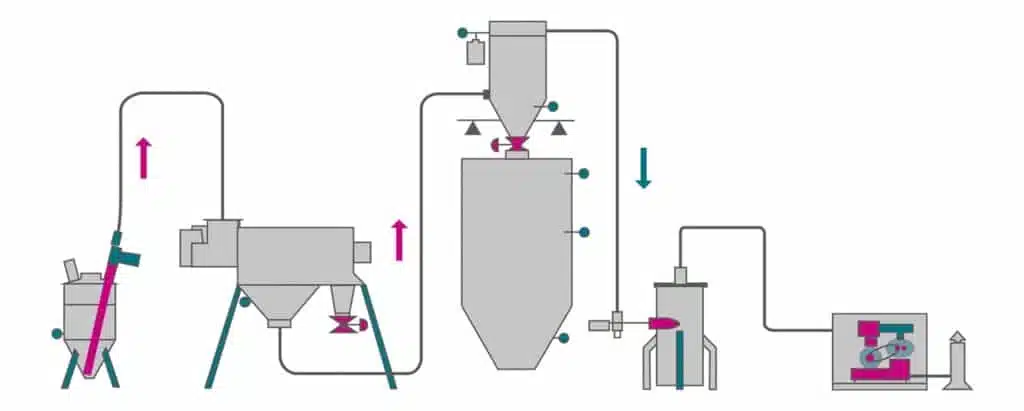

This process of filling molten products into the respective containers is important at Ebbecke Verfahrenstechnik AG after successful pastillation. The suction blower station creates a vacuum in the scale. By opening the shut-off device, the conveyed material is sucked through the suction conveyor line into the pick-up point.

Advantages and disadvantages of pneumatics

Advantages of pneumatics

- Pneumatic drives allow powerless holding with constant force.

- Pneumatic systems are robust against overload and insensitive to temperature fluctuations.

- In most cases, the use of air as the drive medium ensures sufficient cooling of the drive components. Additional cooling is not necessary in pneumatic applications.

- Pneumatic drives have a relatively simple design and are therefore less expensive than electric drives with comparable performance data.

Disadvantages of pneumatics

- Escaping compressed air causes noise. As a countermeasure, the exhaust air can be ducted or discharged into the ambient air via a silencer.

- Depending on the application, complex air treatment may be necessary in some places, e.g. to ensure that the compressed air is free of oil, to limit the particle size it contains to a minimum or to reduce the dew point (otherwise there is a risk of water formation and icing in valves).

Online sources:

https://de.wikipedia.org/wiki/Pneumatik, retrieved: September 27, 2019, 19:50 UTC

https://www.duden.de/rechtschreibung/Pneumatik_Lehre_Mechanik

Literature sources:

1. hydraulics and pneumatics: basics and exercises / Holger Watter / 2015

2. fundamentals of pneumatics / Horst-Walter Grollius / 2012