What is capillary moisture?

Capillary humidity is a term from physics and describes an effect in which water is attracted to and collects in narrow, confined spaces. This effect is also known as the capillary effect. With capillary humidity, the moisture initially dissolves in the smallest cavities and from there spreads throughout the room.

How does capillary moisture develop?

Capillary moisture occurs when water vapor condenses on cold surfaces and adheres to these surfaces in the form of liquid. This is particularly the case when the air temperature is lower than the surface temperature and damp material is present. Poorly insulated rooms or a lack of ventilation systems also encourage the formation of capillary moisture.

Where does capillary moisture occur?

Capillary moisture occurs in buildings whose hydro-insulation is missing or damaged. The most important building materials are porous, the surface tension of the groundwater causes it to rise in the tiny capillaries in the wall building material and also penetrates into the cellar.

The most important signs of capillary moisture build-up

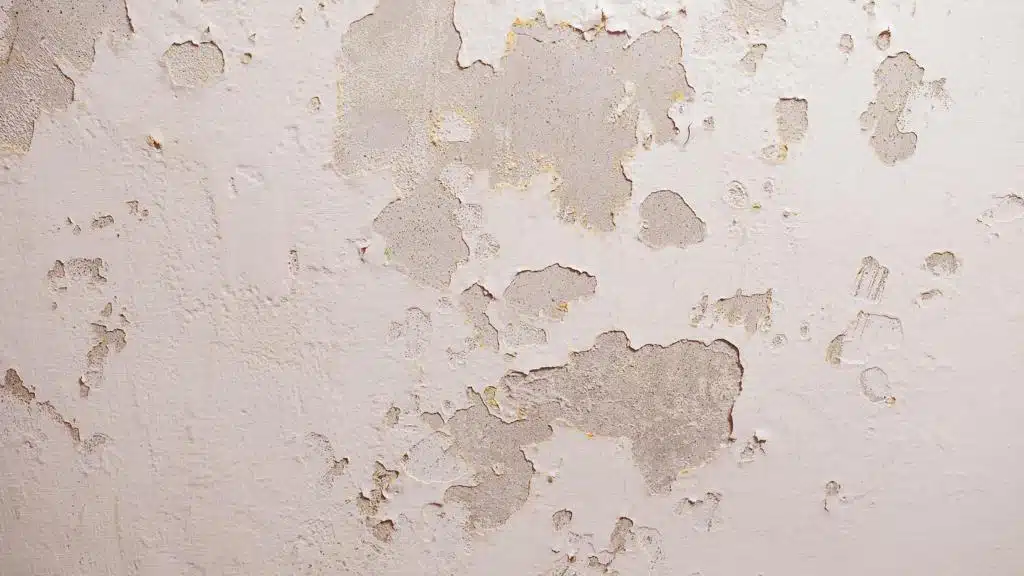

Capillary moisture can be recognized by various signs, such as fine condensation trails on window panes or increased humidity in rooms. Cracks can be seen on wall paint, mold stains and peeling paint also indicate excessive moisture.

- Unpleasant smell of moisture

- Mold formation

- Falling of the plaster from the wall; layering of the walls

- Emergence of lime and nitrate

- Appearance of salt on the wall surface

- Exceptionally cold surfaces

The water, which is enriched with the salts contained in the soil, can rise up to 1.5 meters or more above ground level. It then begins to dry on the wall surface, resulting in the formation of a salt deposit and the chemical decomposition of the wall’s plaster. Frost accelerates this process. New plaster and so-called dehumidifying plaster alone cannot dry damp walls.

How can capillary moisture be eliminated?

There are several ways to eliminate capillary moisture: The first step is to find out where the moisture is coming from and eliminate the cause if possible. Good insulation of the building and opening windows or doors to ventilate the room when the outside temperature is dry can help to reduce the humidity. A heating system can also help to reduce humidity and protect the building against condensation.

However, a specific drying process must be used to effectively remove deep-seated capillary moisture. In process engineering, there are various drying processes such as adsorption drying, evaporative drying or fluidized bed drying. These processes work with different methods and devices – depending on requirements – to effectively dry a specific product or material. For larger areas of application, drying systems with high performance and specially adapted process sequences are available.

Relevance for product manufacturing

The problem of capillary moisture can also affect products or manufacturing processes if moisture penetrates the product and collects on the surface. It often comes from the environment or from the materials used. If the product is not dried properly, this moisture can cause damage and significantly impair product quality.

This problem is particularly common in bulk goods processing and can lead to production downtime and loss of quality.

The best way to prevent capillary moisture in the processing of bulk materials is to optimize the drying process. The choice of a suitable drying process is crucial for this.

Ebbecke Verfahrenstechnik in Bruchköbel uses various sophisticated processes and special systems in the field of contract drying to reliably remove capillary moisture, surface moisture or crystal moisture and achieve optimum drying results. We will be happy to advise you on the possibilities!