Professional contract mixing for efficient production

The mixing of raw materials in different particle sizes, as well as the incorporation of liquids such as oils or emulsifiers, is an important task in process engineering that belongs in experienced hands. Especially when it comes to difficult products, it is crucial to rely on an experienced partner equipped with the necessary technologies to ensure reliable and consistent quality. Ebbecke Verfahrenstechnik offers expertise and reliability in contract mixing and contract coating and can adapt to a wide range of requirements.

We have high-tech machinery at our disposal that enables us to homogeneously mix a wide variety of components. By treating the surfaces of granulate or powder mixtures, we can additionally refine your product and give it other desired properties. Whether as a supplement to your own systems for peak loads or as a complete outsourcing service: We are at your disposal in the field of contract mixing and coating.

Versatile mixing systems for a wide range of requirements

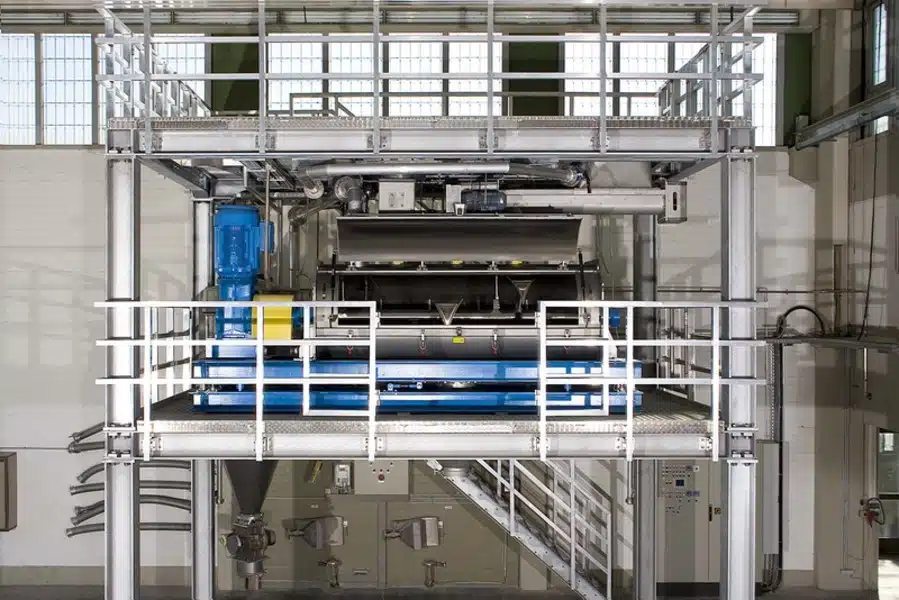

Ebbecke Verfahrenstechnik AG produces mixtures and coatings from various raw materials using efficient and modern mixing systems. We use a wide range of technologies for contract mixing. Our mixing machine park is supplemented by a fully automatic gravimetric measuring can weighing system as well as choppers, nozzle sticks and loading options for various containers. Furthermore, the state-of-the-art ploughshare mixing systems, for example, enable the homogeneous mixing of a wide variety of components.

Overview of Ebbecke mixing systems

- Ploughshare mixer with integrated load cell weighing system and integrated nozzles

- Nautamisher

- Container mixer

- Pan mixer with ribbon blender

- Rhön wheel mixer

- Eirich mixer

- Vortex screw mixer

- Special mixing systems, e.g. for mixing chemical additives, 3D printer applications, food, animal and cosmetic products

Powerful contract mixing with the Drum Mix

Technical data

Mixing room volume:

- System type 1: 9.0 m³ Nauta mixer

- System type II: 3.0 m³

- System type III: 1.2 m³

- Plant type IV: 0.2 m³ rotary mixer

- Filling level: 70 %

- Parts in contact with the product: Stainless steel, polished

- Feeding from big bag, drum or bagged goods via feeding stations and dosing screw; feeding takes place by gravimetric dosing

- Integrated spraying device for liquids

- Number of choppers: 2-4

- Number of mixed streets: 4

Application areas of the Drum Mix plow mixing system

The powerful, flexible and versatile ploughshare mixing systems in the Ebbecke machine park enable the production of granulates and powders from various components. Our systems all have choppers and are also equipped with a nozzle block to enable liquid additives to be sprayed onto the product.

- Production of granulates of defined hardness and abrasion resistance by means of infinitely variable contact pressure regulation

- Guarantee of product homogeneity, avoidance of segregation

- Production of low-dust granules for better handling and improved mixing properties

- Compression of the container volume through compaction with the same active ingredient content

Advantages of application mixing with Ebbecke

- Precise control of all parameters

- Consistently high quality

- Compliance with hygiene standards (HACCP)

- Identical and scalable technology

- Cost and time savings through outsourcing of subordinate processes

- Concentration of your production on core competence

- Some of our mixers can be cooled or heated

- Flexibility thanks to different mixing tools, cutter heads and shaft speeds

Working with Ebbecke Verfahrenstechnik offers you many advantages.

Our different mixing systems guarantee the best possible quality for every application and are also designed to meet the special requirements of difficult products. We would be happy to advise you on which process is best suited to your project and how we can best provide you with our contract mixing services.