What is (wage) pastillage?

During pastillation, molten products are transformed into granules. At Ebbecke in Bruchköbel, this is done using modern systems in the form of pastilles, flakes or coarse sheets, depending on the customer’s requirements. We achieve an efficient conversion process by continuously transferring the molten starting product into granulate form using cooling belts.

Depending on the product, industry and requirements, Ebbecke works with different feeding systems such as the rotator process. Additional equipment for grinding, crushing or shredding is not necessary. In the production of flakes, these are integrated into the machines. This lowers energy consumption, protects the environment and reduces costs.

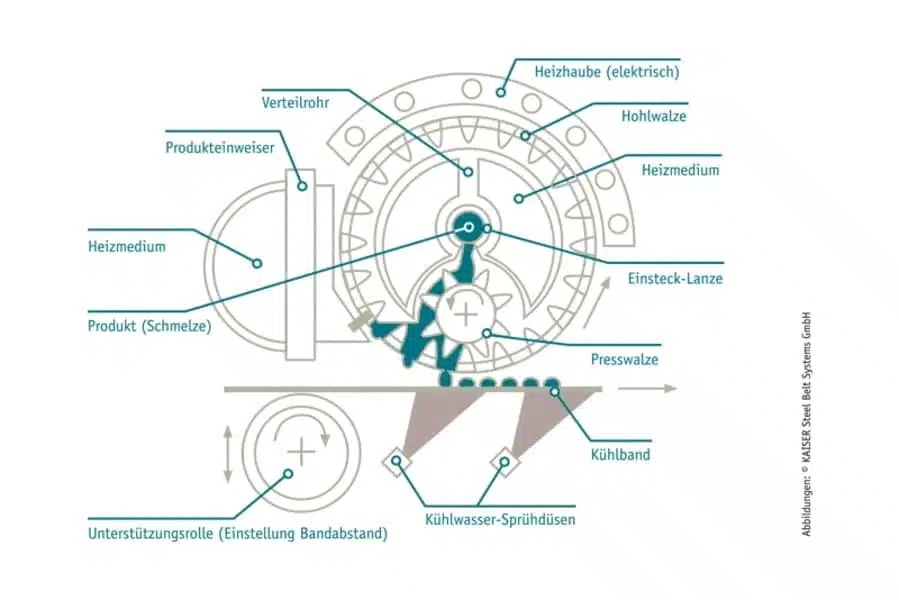

Rotator procedure

The roller technology focuses on an internally toothed hollow roller with holes in the tooth gaps. The meshing of the hollow and press rollers ensures that the pastilles are evenly dispensed via the holes in the hollow roller. As soon as the teeth of the hollow roller and press roller slide out of engagement, a vacuum is created for a brief moment, which favors the pastillation of stringy products.

Advantages of the rotator procedure:

- Ideal for products with a higher melting point

- Due to the possibility of processing higher product viscosities

, the feed temperature can be lowered for many products - Products in a wide viscosity range can be processed with one and the same feeding system

- Ideal for products with solids content and pre-inoculated melts