What is spray drying?

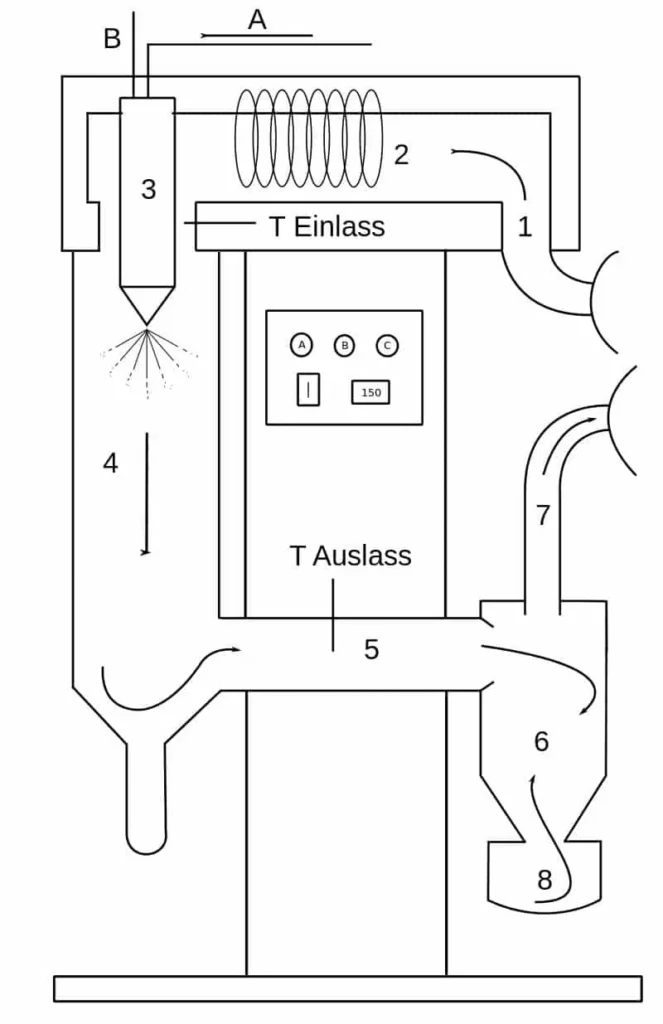

The method of spray drying or atomization drying with the aid of a hot gas stream is used in process engineering to dry emulsions, solutions or suspensions. The result is a fine powder with particle sizes between 5 and 500 my.

Which parameters play a role in spray drying?

During spray drying, complex interactions occur between the liquid starting product to be dried and the heated air in the heating gas flow. In order to influence the structure and size of the particles, device parameters such as the quantity and temperature of the air, the flow rate of the liquid and various parameters of the liquid can be changed.

Areas of application for spray drying

Spray drying is a frequently used process in the food, pharmaceutical and chemical industries and is particularly suitable for sensitive substances such as vitamins or essential oils as well as detergent powders or ceramic powders. There are also numerous other areas of application for spray drying.

Spray drying for food

The principle of spray drying is often used in the processing of foodstuffs. For example, spray drying is a proven production method for drying milk to produce milk powder or coffee or coffee powder for instant coffee.

Using a nozzle, the bulk material to be dried is introduced into a stream of hot air in the spray drying system, which dries it to a fine powder in a fraction of a second. This powder consists of hollow spheres with a large specific surface area, which ensure good solubility for certain products.

Special spray dryers enable production using circulating gas and inertization and have external dryers for post-drying and additional adjustment of the final moisture content. This process is ideal whenever sensitive products in the food or chemical industry, such as vitamins, hormones, proteins and essential oils, need to be processed. All powders produced in this way form tiny hollow spheres (20-200 nm) with a large specific surface area. The dried product has very good solubility after spray drying.

Advantages of spray drying

The outstanding advantages of spray drying are the very fast drying in fractions of a second and the possibility of drying temperature-sensitive substances such as proteins or peptides.

The powders produced during the process have a large surface area, which ensures rapid dissolution: This is very important in the production of pharmaceuticals, for example.

Another advantage is the scalability of the process – from laboratory situations to large industrial scales.

Disadvantages of spray drying

The main disadvantages of spray drying are the comparatively high acquisition costs of the technical systems, which also often require a lot of space, especially in industrial applications. However, these disadvantages can be avoided by outsourcing the service to competent service providers in the field of contract manufacturing.

Spray drying for product recovery

Save energy and costs: When spray drying food, innovative filter systems can be used to filter and recover the very fine dust particles produced during atomization.

Such smart filter processes achieve interesting savings potential through the associated recovery of material and energy, reduce operating costs and thus contribute to a faster amortization of the system.

Spray drying in contract manufacturing

When considering whether a company should buy a spray dryer or not, spray drying as contract manufacturing can be a sensible alternative from an economic point of view. Outsourcing spray drying offers advantages such as certified quality, state-of-the-art technology and demand-oriented production.

Ebbecke Verfahrenstechnik AG offers you various services in the field of contract manufacturing and specializes in the drying of powders and granulates, among other things. We are also happy to develop individual processes for drying your products.

We look forward to your inquiry!